- Ụgwọ nke ụlọ ọrụ Beijing Jinyehong Metallurgical Machanical Equipment Corp.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

Ọla kọpa Mold Tube mejupụtara

Okwu mmalite nke Plating Composite

Ọ na-ezo aka na oyi akwa mkpuchi ọtụtụ. ya bụ, a ga-ekpuchi ihe nke ụdị 2 na tube ọla kọpa n'usoro. A ga-ekpuchi oyi akwa mbụ nke nickel-cobalt alloy na tube ọla kọpa dị ka oyi akwa etiti, dabere na nke a ga-eme oyi akwa nke abụọ nke Chrome dị ka teknụzụ mgbochi-wearPlating:

Ngwakọta ngwakọta bụ nke mkpuchi Chrome siri ike, enwere ụdị abụọ a na-akpọ niclel-cobalt alloy, nke otu bụ usoro amido-sulfonic acid nwere nickel aminosulfonate & cobalt aminosulfonate dị ka akụrụngwa ebe nke ọzọ bụ sistemu sulfuric acid nwere nickel sulphate & nickel. cobalt dị ka akụrụngwa. Nke mbụ dị elu karịa nke ikpeazụ na teknụzụ maka nickel sulphate nwere nrụgide dị elu nwere ike ịpụ na mkpuchi. N'ụzọ dị iche, usoro amido-sulfonic acid nwere nrụgide dị ala nke nkwụsi ike dị mma.

Uru

Ihe mkpuchi nickel-Cobalt dị ka oyi akwa mgbanwe iji mee ka ndụ ngafe nke metal mmiri mmiri dịkwuo elu, n'ikwu ya n'ụzọ ọzọ, dị ka ihe mgbasawanye nke ọla kọpa na chrome dị nnọọ iche, na usoro ikpo ọkụ na oyi, mgbasawanye shrinkage ga-eme ka ọdịda ahụ pụta. site na mkpuchi. Ya mere, tupu mkpuchi chrome, oyi akwa nke nickel-cobalt na-arụ ọrụ ihe nchekwa iji nwee onwe ya pụọ na nsogbu ndị na-apụ apụ, nke na-ebelata mmetụta na mkpuchi ahụ na usoro ikpo ọkụ na oyi na-abawanye ndụ ndụ.

Okpomọkụ: 20℃, (1E-6 / K ma ọ bụ 1E-6 / ℃)

| Ọla | Ihe Mgbasawanye |

| Ọla kọpa | 6.20 |

| Nickel | 13.0 |

| Chrome | 17.5 |

Ngafe ndụ nke igwe mmiri mmiri: 8,000MT (Chrome Plating)

Ngafe ndụ nke igwe mmiri mmiri: 10,000MT (Mkpokọta Ngwakọta)

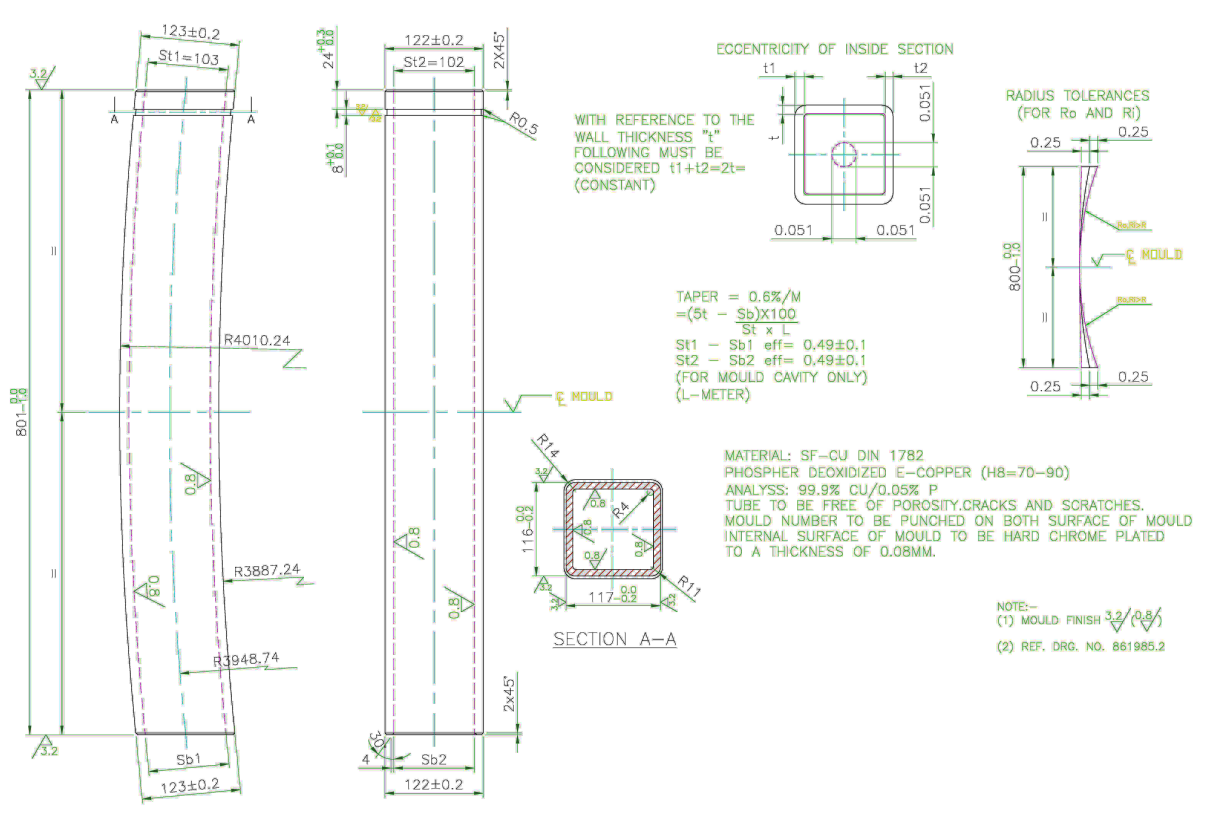

tubes ọla kọpa maka igwe nkedo na-aga n'ihu nwere njirimara mara mma dị ka ndị a:

1. Nguzogide abrasion dị mma;

2. Nagide okpomọkụ dị elu;

3. Ezigbo nguzogide corrosion;

4. Ike dị elu na ike siri ike;

5.Good ikpo ọkụ